Optimized structure design, greatly increasing the surface area of the oil in the vacuum system, and maximizing oil travel in a vacuum system.

By vacuum tank, vacuum pumps, condensate tanks, fluid tanks, air-filling system.

| Model | unit | ZLYC-25-*/** | ZLYC-32-*/** | ZLYC-50-*/** | ZLYC-100-*/** | ZLYC-150-*/** | ZLYC-200-*/** | ||

|---|---|---|---|---|---|---|---|---|---|

| Rated flow | L/min | 25 | 32 | 50 | 100 | 150 | 200 | ||

| Rated pressure | MPa | 0.6 | |||||||

| Rated vacuum | ≤0.095 | ||||||||

| Water content | ppm | 5-30 | |||||||

| Air content | ≤0.2% | ||||||||

| First filtration precision | μm | 100 | |||||||

| Secondary filtration accuracy | μm | 10,20 | |||||||

| Third class micron | μm | 3,5 | |||||||

| Voltage | V | Three-phase AC380V 50Hz | |||||||

| Motor Power | KW | 18 | 26 | 36 | 65 | 65 | 135 | ||

| Weight | Kg | 360 | 470 | 680 | 840 | 960 | 1500 | ||

| Dimensions | cm | 125x92x160 | 430X350X950 | 135x98x140 | 150x106x180 | 160x108x210 | 180x120x220 | 200x120x220 | |

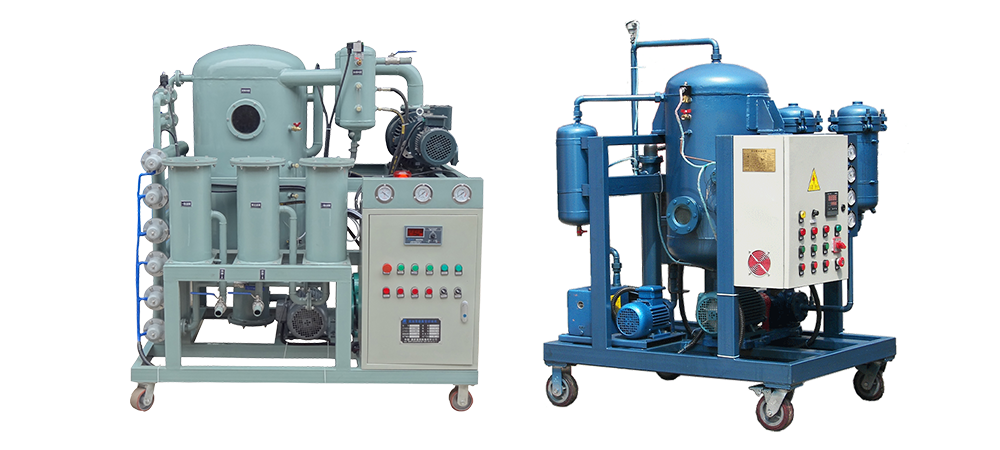

1. Vacuum System: By vacuum tank, vacuum pumps, condensate tanks, fluid tanks, air-filling system.Optimized structure design, greatly increasing the surface area of the oil in the vacuum system, and maximizing oil travel in a vacuum system. The oil in the water and gas are fully overflowed. This machine adopts advanced defaming system so oil filter at work will not appear similar products widespread phenomenon of injection.

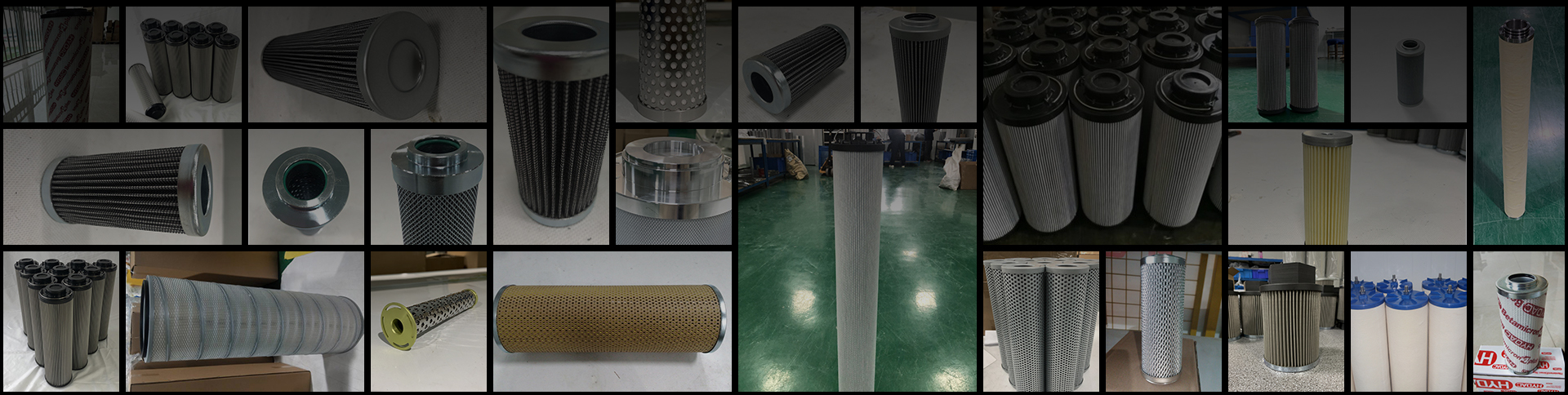

2.Filtration system: Using three filter, coarse filter inlet to protect the pump and extend the life of the main filter. After the pump has two fine filter, so the oil quickly reach high cleanliness. Using special gradient filter pore glass fiber material that can be layered filter particles of different size, which greatly improved the life of the filter. The filter has a perfect structure, which can effectively reduce the surface velocity filter, access to stable filtration accuracy.

3. Heating system: Segmented gradual heating surface heat load is small 1.0W / cm2, the oil does not overheat causing deterioration. Oil temperature can be adjusted at 0 ~ 100 ℃, automatic control, and a protective device, the amount of oil is too low today automatically stop working, to avoid damage caused by dry heater.

4. Automatic control system: The machine uses the frequency, level transmitters, temperature sensors, vacuum degree sensing instrument, such as a series of automatic control instruments of various information acquisition device run by the central processor for processing, automatic control of the whole equipment run and monitor the operational status of equipment. The unit comes with a variety of protective devices (overload, overvoltage protection, phase sequence protection, abnormal operation shutdown protection) to ensure safe operation of equipment.

5. The whole structure: Machine integration bridge structure, reducing the volume. Holistic removable tank, ensure that the ground without oil operations, reduce environmental pollution. There are mobile, fixed, fully enclosed, vehicle type, and so many models to choose from.

Applications

1.Oil purifier of turbine oil and transformer

2.In addition to water, hydraulic and lubricating oil filter impurities

3.Comprehensively improve the cleanliness of hydraulic lubrication system

4.Various types of oil regeneration purifier

Power plant

Petrochemical

Machine made

Traffic

Metallurgical Mine

Lifeierte oil machine can produce 2000 sets of oil filtering equipment and other fluid purification equipment every year. We are one of the global competitive companies focusing on the research and manufacture of high-tech oil purifiers. The equipment is exported to nearly 50 countries all over the world! Provide online technical support and on-site service engineering to support customers' operational needs.

We provide various oil filter models. Our product sizes and materials are customized according to needs, and the capacity ranges from less than 1200L/H to 24000L/H.

→1. We are a manufacturer of oil purifiers, factory direct sales, no intermediate links, competitive prices.

→2. Our equipment is imported accessories, and the quality of the products produced is stable.

→3. To ensure on-time delivery, we can provide the best quality service, transportation, document preparation, etc.

→4. We will answer your inquiry within 24 hours.

→5. With more than 12 years of R&D experience and a professional technical team in the oil filter industry, our customers feel relaxed and happy when working with us.

Discover the story behind the people that are making the Filsonfilter trust on the next level

great,How and why they do what they do.

High Viscosity Fiker Cot

Denmark Cusome

5 stars from 100 reviews

High Viscosity Fiker Cot

Denmark Cusome

5 stars from 150 reviews

High Viscosity Fiker Cot

Denmark Cusome

5 stars from 200 reviews